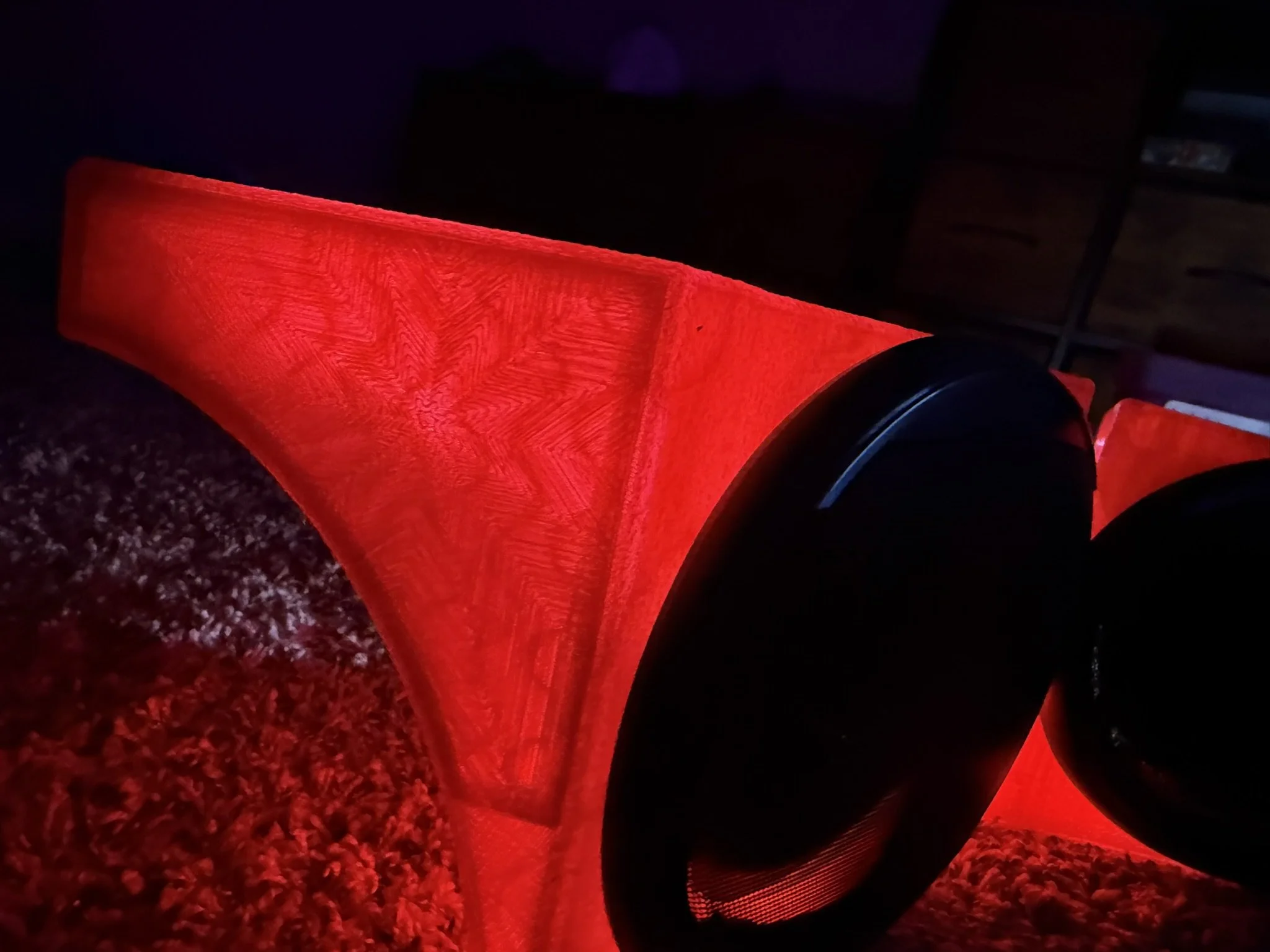

These are the Demon Speakers — a pair of red-glowing 6×9 rear speakers exclusively made for the Corvette C3. Designed to call to you in your dreams, these aren’t for everyone — punks driving other cars will just have to imagine them. This one-of-a-kind set includes pre-installed Pioneer A-Series 6×9 speakers, fully mounted and ready to go, along with all required mounting hardware. Each enclosure features integrated LED lighting, pre-wired with six 3-LED light sources per speaker to deliver an even, all-over glow with no dead spots. This is the first set of its kind in the world, blending aggressive style, engineered structure, and modern audio into a single statement piece. $400 for the complete set, plus shipping.

C3 Corvette Tuck-Away Rear Speaker Boxes (1968–1982)

Rear Speaker Enclosures — Not Subwoofer Boxes

If you’ve ever tried to upgrade the rear speakers in a C3 Corvette, you already know the problem.

The factory rear speaker locations were designed around extremely shallow, low-power speakers. Modern 6×9 speakers are deeper, heavier, and require proper enclosure geometry to sound right and stay mounted long-term. That mismatch is why so many factory-style and aftermarket solutions end up loose, poorly positioned, rattling, or literally falling out.

These rear hatch speaker boxes were designed to solve that problem correctly — from the enclosure outward, not as an afterthought.

These are true enclosed speaker boxes, not faceplates, not cosmetic panels, and not hollow shells.

Designed for Modern Speakers — Not 1970s Hardware

Most original and reproduction “6×9” solutions were never built for real full-size speakers. They relied on smaller drivers mounted to plates to fake the size while avoiding depth.

These enclosures are designed around modern, full-depth 6×9 speakers, with proper support, air volume, and mounting depth — so the speakers install securely, perform correctly, and stay put.

Each speaker is housed in its own independently sealed chamber, which is critical for:

Preventing back-pressure damage

Maintaining clean mid-bass response

Eliminating cross-interference between speakers

Long-term acoustic stability

No shared airspace. No compromises.

Optimized Tuck-Away Geometry — Built for Real Clearance

Rather than forcing a strict textbook 45-degree angle, these enclosures were designed with maximum tuck-away clearance as the priority.

The geometry intentionally pushes the boxes deeper into the hatch area, preserving valuable rear storage space — especially important for T-top storage, where clearance actually matters.

Many competing designs focus on achieving a perfect angle at the expense of usability. These do the opposite. The profile is optimized to sit deeper and tighter in the hatch, providing more clearance than most angled alternatives while still maintaining proper enclosure volume and speaker performance.

The result is a cleaner fit that doesn’t compromise how the car is actually used.

Key dimensions:

Maximum height: 9 inches (228.6 mm)

Depth: 9 inches (228.6 mm)

Overall width: approximately 36–37 inches, depending on final fitment

Segmented Structural Design — Not a Hollow Shell

These enclosures use a segmented structural design, where each section is a rigid, load-bearing component that locks together to form a unified enclosure.

This approach:

Increases overall stiffness

Reduces panel resonance

Prevents flex under speaker load

Eliminates reliance on large, unsupported hollow cavities

Each segment is structurally independent, meaning strength and acoustic stability are built into the geometry itself — not dependent on thickness or added mass.

Advanced Additive Manufacturing — Not Hobby Prints

These are not thin-shell or decorative prints.

They are produced using advanced additive manufacturing techniques selected specifically for acoustic and structural performance:

0.8 mm nozzle

Intentional over-extrusion

Ultra-low infill (~2.8%)

Resulting in dual walls approximately 1.4 mm thick each

Once fully printed and sealed, the structure becomes extremely rigid.

This method creates:

Lightweight but highly impact-resistant enclosures

Internal geometry that resists flex and vibration

Strength comparable to — and often exceeding — MDF

This is material engineering through toolpath control, not plastic boxes.

Acoustic Engineering by Design — Not Guesswork

The enclosure geometry is informed by years of experience in acoustics, waveform behavior, and sound engineering, combined with a Master’s degree in Architecture.

That combination allows for:

Triangulated structural geometry

Vibration-resistant enclosure design

Acoustically stable speaker chambers

Internal forms that MDF and flat panels simply cannot replicate

Flat panels rely on mass.

These enclosures rely on geometry.

Why This Beats MDF & Fiberglass

Traditional MDF enclosures are:

Heavy

Moisture-sensitive

Prone to warping and swelling

Dependent on mass instead of structure

Fiberglass often introduces:

Inconsistent thickness

Resonance issues

Long-term brittleness

These enclosures:

Do not warp or swell

Resist panel resonance

Maintain acoustic integrity over time

Deliver cleaner sound and tighter response

The era of MDF-only audio fabrication is ending.

Installation — Designed to Mount Cleanly

Installation is designed to be secure, clean, and reversible, using factory mounting points wherever possible.

Installation Overview

Mount the bracket plate

The supplied mounting plate bolts directly to factory frame locations using existing screw holes.Position the empty enclosure

Set the enclosure in place on the mounting plate.Mark and drill pilot holes

Align the enclosure, mark the mounting points, and drill pilot holes.Speaker mounting options

Speakers may be mounted:On the face of the enclosure, or

Inside the enclosure

Internal speaker mounting (if used)

The front cap snaps off to provide access.

Mount the speaker inside the enclosure.

Fasten the enclosure to the mounting plate using the access openings beneath the cap.

Snap the front cap back into place for a clean, finished edge.

This system allows the enclosure to mount securely without visible fasteners while still providing full access during installation.

Speaker & Grille Compatibility

Designed to work with the standard grilles included with most 6×9 speakers — no proprietary or hard-to-replace grilles required.

Both internal and external speaker mounting configurations are fully supported.

Customization & Visual Options

35 solid color options

4 translucent color options

(Translucent versions are the same price and do not include LEDs)Covered version available in 9 fabric colors

Optional integrated LED lighting

Optional custom grilles and accessory add-ons

Clean, modern aesthetics that complement interiors rather than clash with them — far more adaptable than carbon fiber faceplates or molded panels.

Built Solid — Not Thin Shells

Each enclosure is a structural build, using nearly a full roll of filament per box. These are designed for durability, stability, and long-term reliability — not minimum material usage.

Pricing

Standard (Uncovered): $200

Covered Version: $240

(Comparable black-only options routinely sell for $300+ when they’re even available.)

Ordering Note

Due to the wide range of color and customization options, orders should be confirmed directly before checkout to ensure correct color selection and finish.

📩 Contact: kenbessmer@yahoo.com

You can also reach out via Facebook to confirm options before ordering.

Be sure to check the page to see custom glowing effects and other C3-specific parts currently in development.

The Bottom Line

These rear hatch speaker boxes are:

Stronger

Lighter

More acoustically stable

More customizable

More affordable than traditional solutions

They’re designed by someone who understands C3 interiors, modern audio requirements, and structural acoustics — not just catalog fitment.

This is the future of classic car audio enclosures.